Shoppers might know the model, pressure, and energy of their favourite vape, topical, or tincture, however they’re unlikely to know a lot concerning the strategies that remodel crops into concentrates. That is the realm of extraction artists, and their strategies can have as a lot influence on the product’s results because the rising circumstances that produced the vegetation.

Know-how has given extractors new methods that usually mimic excessive climate circumstances: excessive humidity, dense fog, arctic blasts, high-pressure programs, and sirocco headwinds robust sufficient to tear the trichomes off a plant. Every methodology has its adherents, all of whom pursue the identical purpose: a scalable, cleaner, cheaper, and safer course of that yields the purest potential oil.

“Among the many quickly increasing hashish markets, extraction is arguably probably the most lively space of innovation and development,” in line with a report from Prohibition Companions, which carefully screens the business in Europe and North America.

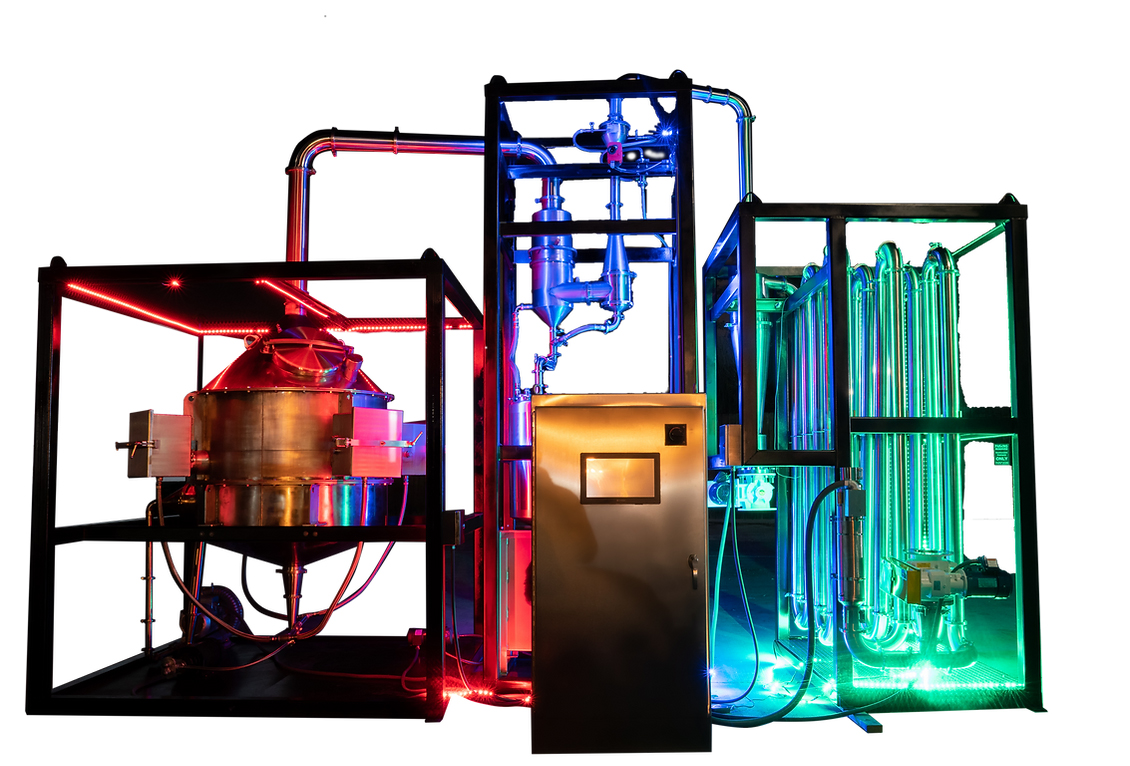

Extraction is an more and more subtle course of, and fashionable hashish extraction machines are costly. Most farms and producers nonetheless outsource, however others are shopping for new turnkey programs that permit them to maintain the method inside their management. Actually, there are such a lot of strategies—wiped movie, vapor, and vacuum-steam ovens, to call just some—that competitors is spiking within the sector.

At current, a lot of the competitors focuses on economics as tools producers race to refine know-how that can assist producers scale back prices in an more and more difficult market. Demand for hashish and hemp concentrates has grown prior to now three years as extra states come on-line; 90 % of People now have entry to some type of authorized product. Gross sales of vape cartridges, that are highly effective and discreet, are consuming into the marketplace for flower. And something with “miracle” CBD is off the charts as customers demand specialised merchandise to deal with the whole lot from insomnia and ache to nervousness in individuals and their pets.

However whereas shopper adoption is climbing steadily in practically all authorized states, the availability is starting to outpace the demand in markets the place officers are issuing a vast variety of cultivation licenses and farmers are coaxing greater yields. Wholesale flower costs are falling in a number of the largest markets—California, Colorado, Oregon, and Washington, amongst others—and operators throughout the nation are below stress to chop prices to take care of market share.

To assist producers attain effectivity and income targets, tools producers are nudging them away from small-scale lab manufacturing towards cheaper and quicker industrial programs. G&D Chillers, which served companies within the beverage alcohol house earlier than partaking with the hashish business, has greater than three a long time of expertise working with large-scale extraction operations.

“We’ve bought fundamental economies of scale to contemplate,” stated Scott Timms, G&D’s lead gross sales engineer. Producers have to “produce extra and pay much less” per unit.

“We began with some industrials, then distilleries, then craft beer and wine corporations,” stated Timms, who famous the corporate’s hashish enterprise took off when extractors began to acknowledge the significance of ultra-low temperatures. “We started getting extra requests from the hashish house about 5 years in the past and began shifting towards even decrease temperatures.” He means actually low temperatures, as in -58°F. The corporate is designing tools that can carry the temp all the way down to -80°F.

G&D sells specialised tools to extractors, most of whom discover the corporate on social media and at commerce exhibits. Hashish is about one-quarter of the corporate’s enterprise, in line with Timms, and the proportion is rising—not least as a result of customers are discovering the position terpenes play within the results they expertise. The fragrant compounds, that are destroyed by excessive temperatures, have develop into the holy grail of cultivation and processing, acknowledged—however not fully understood—because the plant’s toolkit for style, well being, and helpful results.

Refined customers and researchers are turning to those smaller constructing blocks to make extra centered merchandise. Wish to sleep? Search for linalool. Courting sofa lock? Myrcene. Affected by irritation? Humulene’s bought you coated. Every terpene—and there are scores of them—has particular properties affecting a product’s therapeutic worth and person expertise.

“Excessive chilling preserves fascinating terpenes and cannabinoids,” Timms stated. “[Our systems] additionally pull out fat and lipids, chlorophyll, and [other undesirable components] to maintain them out of the method.”

Terpenes have been simply casualties of manufacturing till a decade in the past, when researchers and growers took an interest within the clear, sticky substances. In the present day, terps are extracted from the plant earlier than it’s processed and reintroduced later, like seasoning, to concentrates.

Terplandia is a part of a comparatively latest development: the ascent of corporations that produce “after-market” terpenes. The corporate doesn’t manufacture tools. As a substitute, it extracts terpenes from industrial hemp after which provides labs, researchers, business formulators, and terpene-obsessed customers who need to compound their very own aromatherapy, concentrates, and edibles. Hemp terpenes are authorized in all fifty states as a result of they include no THC.

In response to Terplandia founder Taher Afghani, “There’s lastly a whole lot of analysis on terpenes. We’re simply starting to scratch the floor of their health-related, beauty, and perfume advantages.”

Afghani prefers to work straight with farmers. The very best apply, he stated, is to reap terpene-laden flowers whereas the plant continues to be within the floor—ideally earlier than daybreak, when the temperature continues to be cool. Sticks and stems are discarded instantly, and the flower is delivered into the chamber of Terplandia’s vacuum-steam distillation system. Reducing the stress within the chamber lowers the temperature wanted to create steam, which means the biomass is processed at roughly one-third the warmth often employed throughout extraction. The method removes the terpenes from the buds and extracts chlorophyll, waxes, and different undesirable byproducts. The result’s run by way of a gentle dryer or unfold out in a room with dehumidifiers.

Many extractors use vacuum steam to separate terpenes and cannabinoids from the biomass, however Boulder Creek Technologies isn’t amongst them. As a substitute, the corporate makes use of a vapor fog. The distinction, stated cofounder and Chief Government Officer Rick Bonde, is that cool fog won’t degrade delicate elements like scorching steam can. Boulder Creek’s Vapor-Static system begins with a flash of heat air that’s shock-cooled instantly. An electrostatic precipitator pulls out undesirable sugars and waxes by breaking them into droplets and dissolving them into the fog. As a result of oil and water don’t combine, it’s simple sufficient to separate elements on this type.

Bonde stated the Vapor-Static system preserves THC, CBD, and different cannabinoids—however not heavy metals or mould—within the oil. “It’s a fragile steadiness,” he stated. “We’ve to hit the tremendous steadiness with temperature and publicity time so we are able to carry the cannabinoids with minimal harm.” He acknowledged terpenes take a beating.

Many concentrates have to be refined a second time to take away solvents and different undesirable elements that survive the primary cross. Bonde stated the additional step shouldn’t be all the time obligatory with the vapor course of. “At this level, different oils are thick and black like motor oil,” he stated, whereas Boulder Creek’s course of produces a darkish amber product. Not like oils extracted with ethanol or carbon dioxide, he stated, Vapor-Static’s oils don’t essentially require a second cross to take away solvents and waxes, a course of often called winterizing.

In response to Bonde, the oil can go straight into edibles or be additional refined for a pale yellow or clear distillate for vape cartridges and different makes use of. Reducing out the second extraction saves each money and time.

Though most extraction programs have been tailored from these used to provide meals substances and important oils, Boulder Creek designed its tools from scratch to deal with the particular wants of a specialised business. “Hashish is a quickly evolving know-how,” Bonde stated. “Relatively than perfecting an older tech, we began from the bottom up.

The vapor know-how is nearer to the commercial processes used to lure pollution earlier than they’re emitted from smokestacks, Bonde stated. His brother, Steve Bonde, a chemist and Boulder Creek’s chief know-how officer, spent practically three years creating the system, primarily in response to a schism over using solvents, that are environment friendly and efficient brokers for separating hashish elements but in addition might set off environmental and well being issues.

Extraction usually depends on risky natural compounds (VOCs) together with ethanol and hydrocarbons like butane, propane, and hexane to separate terpenes and cannabinoids from wax, sugars, and different waste supplies which will have an effect on the ultimate product’s properties. Carbon dioxide, additionally thought of a solvent in its liquid type, is non-flammable and non-toxic. Some extractors think about it a safer different, not just for merchandise meant for human consumption but in addition for extraction employees. Strategies utilizing solvents presently are the commonest extraction methods, and proponents say the weather will not be dangerous if they’re used correctly and the ultimate product is cleaned nicely. Lab assessments mandated by state rules are supposed to stop unsafe ranges of VOCs from creeping into the availability chain. Solvents often are purged in a secondary run, a course of some complain additional degrades the fascinating elements of the plant or leaches efficiency.

Boulder Creek’s electrostatic precipitator eradicated the necessity for solvents. “We knew we needed to go solventless,” stated Rick Bonde. “Shoppers are beginning to demand it.”

Professional-solvent extractors say their processes produce a stronger product that retains most of a flower pressure’s taste at a decrease price than solventless programs can supply. Butane hash oil, or BHO, extraction is most popular by many large-scale extractors as a result of the programs are scalable and versatile.

“Solvents aren’t essentially unhealthy if they’re pure and correctly used,” stated Ben Britton, CEO and director of improvement for PurePressure, a division of agricultural know-how company Agrify. “However when customers begin to consider solvents and components, they don’t need them.” That is notably true of subtle clients who don’t thoughts paying extra for the merchandise they devour. An extract produced with out solvents instructions the “highest worth on the shelf,” stated Britton, whose firm makes a speciality of solventless know-how. PurePressure’s sister firm, Precision Extraction, manufactures BHO extraction tools. “It’s essential to know the place your market is.”