Within the nascent days of the hashish business, pioneers relied on sheer dedication and guide processes to serve sufferers in want. Amidst authorized uncertainties, early efforts had been strictly hands-on, from trimming buds to managing affected person information with pen and paper. But, because the business matures, the tide is popping towards innovation and effectivity, propelling companies into a brand new period of automation and synthetic intelligence (AI).

Impressed by conventional industries together with agriculture, prescribed drugs, and shopper packaged items, operators have adopted applied sciences that streamline operations from plant cultivation to packaging and logistics. The shift is not only about saving time and chopping prices. Automation, significantly when mixed with AI, additionally helps refine product high quality to satisfy operator and shopper expectations.

Over the previous a number of years, because the business has matured and turn into exponentially extra aggressive, operators have leaned into automation in an enormous approach, particularly within the cultivation and manufacturing verticals. Two of probably the most energetic areas for analysis and growth are robotics and synthetic intelligence (AI).

Robotics

The time period “robotic” arose from the outdated Church Slavonic phrase robota, that means “servitude,” “pressured labor,” or “drudgery.” Though we regularly consider robots as humanoid automatons straight out of science-fiction motion pictures, at their most simple robots comprise any automated machines or processes that free people from tedious or repetitive duties. And so they needn’t exist in bodily kind. Software program applications that mechanically work together with social media are referred to utilizing the informal abbreviation “bots.” Textual content-based digital customer-assistance brokers have been dubbed “chatbots.” Methods that compile and analyze knowledge or function environmental controls additionally might be known as bots, as may the software program “brains” that assist automobiles function safely, monitor upkeep wants, and diagnose issues. By offloading widespread, repetitive duties like these onto automated programs, people preserve time and power, cut back stress and tedium, and might focus mind energy and reminiscence on different mission-critical duties.

“Your workforce can do much more than sitting in a circle and rolling the identical factor 500 occasions a day,” mentioned Tomer Oliel, director of operations for automated irrigation options supplier RootsTalk. “I don’t see many negatives to elevated automation. You release time and labor, which implies you can begin taking up issues which might be somewhat extra significant to your firm’s growth.”

Extra importantly, automation could make the distinction between revenue and loss in quickly rising industries with slim margins. Automation hastens manufacturing, decreases the potential for errors and accidents, will increase consistency, and reduces labor prices.

“It’s troublesome for operators with out automation to compete,” mentioned Sorting Robotics’ founder and Chief Government Officer Nohtal Partansky. “The distinction may be as important as combating weapons with bows and arrows: It’s a slaughter.”

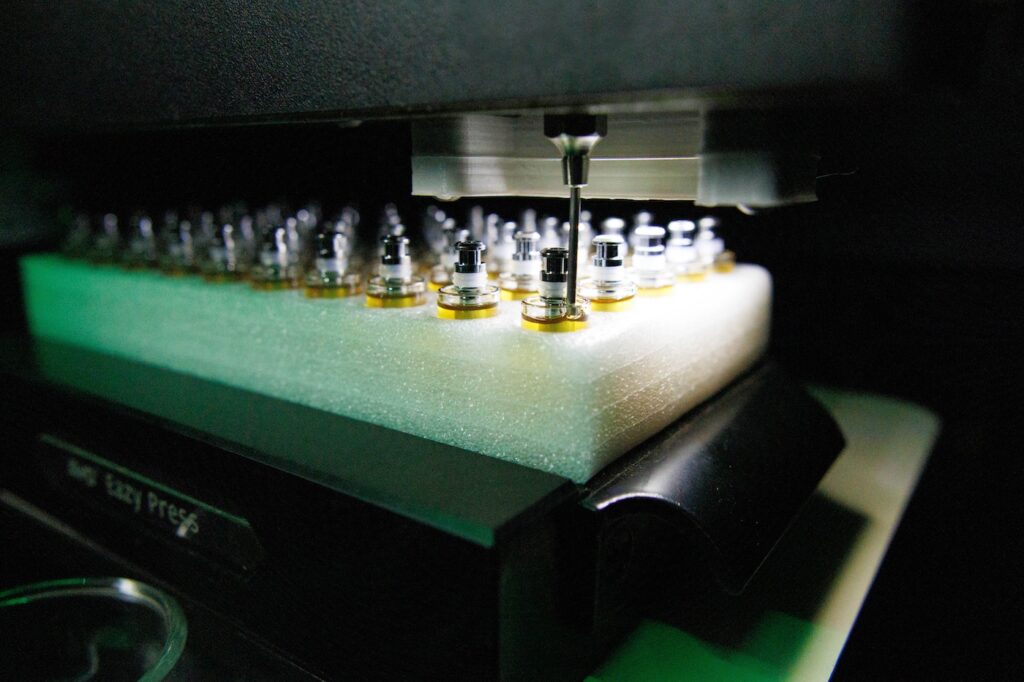

Partanksy and his workforce developed one of many business’s first manufacturing robots designed for a specialised use: producing coated pre-rolls. With the help of a single operator, the Stardust robotic can produce as much as 960 kief-coated joints per hour. The machine doesn’t expose the uncooked supplies or the operator to contamination, and the completed merchandise are uniform, in contrast to their hand-dipped counterparts.

Mixed with an automatic pre-roll manufacturing system like Hefestus’s AuraX, which may produce as much as 2,000 Dutch-crowned pre-rolls per hour whereas lowering staffing wants by as many as sixteen folks, the potential for per-unit price discount is sizable, even incorporating the preliminary price of the tools.

The pre-roll sector is especially ripe for automation. Now the third hottest product class in the USA behind flower and vapes, pre-rolls accounted for almost 20 p.c of complete 2023 U.S. gross sales and a whopping one-third of gross sales in Canada. Pre-roll manufacturing historically has been labor-intensive, requiring meticulous handiwork to make sure consistency in weight, density, and form, however machines have revolutionized the section. Along with Hefestus, corporations like Futurola have developed superior rolling options that improve not solely productiveness but in addition consistency and product high quality. Futurola’s Knockbox 3/300 system, for instance, can fill and pack 300 pre-rolls in two minutes, with a variance in weight between joints of lower than 0.02 grams.

“A pre-roll must be constant each time, and people are usually not that,” Oliel mentioned. “We’re all totally different; we carry totally different feels and touches to our work. With automation, you’ll be able to improve productiveness, consistency, and your total buyer expertise.”

In fact, elevated manufacturing output capabilities require corresponding will increase in uncooked supplies. Automation, and significantly robotics, performs a pivotal position there, as nicely. Cultivation has turn into a veritable hotbed of innovation, pushed consistently ahead by not solely financial but in addition ecological imperatives. Automated programs now management lighting, irrigation, and local weather, optimizing plant progress circumstances and maximizing yield whereas minimizing useful resource waste.

Neatleaf’s Spyder, an semi-autonomous robotic platform, induced fairly a stir upon its debut late final 12 months. Mounted at 4 factors above the cover, the platform’s cable-based multisensor drone-like inspector capabilities like a soccer stadium’s “eye within the sky,” consistently roaming and capturing tens of millions of knowledge factors because it displays each plant in an indoor develop, whatever the room’s measurement.

In response to Neatleaf founder and CEO Elmar Mair, crop loss can cut back a develop’s output by as a lot as 20 p.c, and a considerable quantity of crop is misplaced on account of pests or illnesses not noticed and addressed rapidly sufficient by human laborers—regardless of how painstakingly they look at their leafy expenses. Due to the diploma of consideration to element required, guide examination takes time, and time may be an enemy in environments requiring moment-to-moment precision. Consequently, the business loses billions to crop injury yearly, Mair mentioned.

Neatleaf’s robotic addresses all of that. Aided by AI, the system supplies real-time, actionable insights about the whole lot from carbon dioxide focus and relative humidity to leaf and air temperature. Heatmaps can determine microclimates and systemic points in a room, serving to growers acknowledge points rapidly and handle them earlier than bother spreads.

The aim, Mair indicated, is to offer human oversight, however higher, stronger, and sooner. “The measure of ‘high quality’ relies on people,” he mentioned. “People attempt to perceive what’s happening within the develop house; our system depends on that understanding to detect root causes and work out options. Not a number of specialists are in a position to try this, and in the event that they’re already swamped with repetitive duties simply to maintain issues shifting alongside, the business suffers from a significant bottleneck.

“With the ability to detect and perceive viruses, micro organism, and illnesses early on so you’ll be able to handle [a problem] earlier than it spreads—that may change the crop loss panorama considerably,” he added.

Synthetic intelligence

Like each different business on the planet, hashish is leaning into synthetic intelligence to drive efficiencies and unlock new incomes potential. AI and automation make significantly potent companions.

“Stock and manufacturing are the place AI makes a big distinction,” mentioned Marcus Tillson, chief working officer for end-to-end extraction options supplier Root Sciences. “It’s nice at taking bigger datasets and figuring issues out from there to learn your organization.

“Taking a step again from hashish, simply have a look at the mainstream technological breakthroughs we’ve seen because the pre-Industrial Age,” he continued. “Every one will get sooner and extra advanced, and people developments are a lot extra impactful for us right now. Joe Common didn’t must wrestle too laborious to grasp innovations of the previous. A horse and cart had been straightforward to determine, however a automobile? Not a lot. The extra we progress as a society, the much less possible Joe is to intuitively perceive rising applied sciences.”

That’s the place AI may be vastly helpful. Instantly Joe has an simply accessible, biddable digital companion who will help him make sense of what as soon as was arcane. Even the best machines consistently generate knowledge: revolutions per minute, time to finish a activity, error fee, et cetera. Harnessing and analyzing that knowledge in actual time can present operators with perception that may take people days, weeks, or months to succeed in on their very own. AI reduces friction, permitting automation to provide even better effectivity. With better effectivity comes the power to scale and produce extra income at a decrease price per merchandise.

“The way in which any business ought to strategy automation and AI-enabled effectivity instruments is to start out on the lookout for the lowest-hanging fruit—that’s, the simplest course of to automate,” mentioned Ryan Hoitt, founder and CEO of cart-filling machine producer Vape-Jet. “Then transfer on to the subsequent piece, and preserve evaluating as you go.

“AI goes to maintain bringing huge efficiencies to enterprise operations,” he added.

Hoitt cited an instance: The Vape-Jet workforce developed an AI-assisted bot for his or her workplace Slack channel. The bot permits customers to sign up and request full breakdowns of technical assist points, together with the complete historical past of a problem, a abstract of progress that’s been made towards a decision, and former customer-support requests that includes comparable points with commentary about similarities and variations and the way these points had been resolved. This all occurs immediately, inside seconds of the second a workforce member clicks “assist” on the interface. Then, the bot generates urged troubleshooting steps and hyperlinks to useful resource documentation. The system helps Vape-Jet’s workforce help purchasers rapidly and with a lot much less friction than people may obtain on their very own.

“Because of AI, I’ve been in a position to preserve my workforce actually lean. As a result of we want to give attention to firm progress somewhat than menial duties, I be sure that we’re forward-leading in the case of implementing these kinds of instruments,” Hoitt mentioned. “From an workplace admin perspective, we accomplish as a lot as groups ten occasions our measurement accomplish.”

Due to the complexity of the processes, AI is barely in its use-case infancy in extract manufacturing. However with its potential to research large quantities of knowledge virtually instantaneously, the know-how may show transformative for extraction labs and shoppers.

“As this know-how improves, we are able to get much more explicit about what we’re going to extract from the vegetation,” mentioned Marc Beginin, founder and CEO of Prodigy Processing Options, which designs and builds automated extraction programs. “The entire strategy of placing collectively a consumable good, particularly if it’s used to deal with a specific ailment, will turn into a lot much less strain-dependent. All you need to do is have a look at the pressure’s compounds and take into consideration what your sufferers want, and you may pull from a wide range of vegetation.”

Beginin is a big-picture sort of man. He envisions AI’s affect on his sector beginning nicely earlier than biomass meets machine. “[AI] can cut back the price of the develop and, in flip, decrease the associated fee for the top shopper,” he mentioned. “Because of this, weed turns into extra accessible. Well being and livelihood are now not primarily based on the supply of a specific pressure. AI can analyze the effectiveness of various hashish extracts, and new strains might be designed for particular therapeutic functions.”

Labor points

Automation and AI current virtually limitless potential for companies, however employees are considerably much less enthusiastic. As machines assume duties beforehand carried out by people, an underlying concern of decreased employment alternatives grows. Staff fear “good machines” will exchange them.

The priority is just not unreasonable. A examine carried out by MIT economists Daron Acemoglu and Pascual Restrepo discovered about 400,000 employees had been displaced by manufacturing facility automation within the U.S. between 1990 and 2007, at a fee of about 3.3 employees per robotic. In response to Time journal, as many as 42 p.c of the 40 million American jobs misplaced in the course of the peak of the COVID-19 pandemic had been changed by automation.

However know-how has been displacing human employees for effectivity’s sake because the daybreak of the Industrial Age. A mechanical system known as the Spinning Jenny changed the laborious strategy of hand-spinning yarn within the 1770s, revolutionizing textile manufacturing. James Watt’s modifications to steam-engine know-how led to the rise of factories and the introduction of mass-produced items—a state of affairs Henry Ford additional refined by introducing assembly-line processes. Throughout the twenty-first century, as a part of what some have dubbed the Web Age, automated toll cubicles changed human attendants on turnpikes nationwide. Kiosks displaced some fast-food servers, and the web killed most journey businesses. In hashish, mechanized flower-trimming supplanted some hand-trimmers regardless of the fragile nature of the job.

Staff tailored by studying new expertise. In any case, regardless of how subtle some automated applied sciences are, machines are usually not but able to actually autonomous habits—even after they’re partnered with AI.

“I don’t assume jobs might be completely displaced,” mentioned Prodigy’s Beginin. “People are more durable to interrupt than robots. You’ll at all times want oversight to ensure your machine is doing its job.”

As a result of people nonetheless should oversee, program, and preserve automated tools, forward-thinking corporations are investing in coaching applications that equip their workforces with the abilities essential to function and handle new applied sciences. The strategy not solely mitigates the affect of job displacement but in addition opens new profession alternatives inside the business.

Human nature has pushed technological growth and deployment ahead because the invention of the wheel. As Vape-Jet’s Hoitt noticed, change is inevitable.

“From an moral standpoint, I consider one of the best ways ahead is societal change fueled by AI and automation,” he mentioned. “Fairly than wallow on this in-between interval, let AI come for our jobs. It’s going to occur ultimately anyway. Whether or not we make {that a} lengthy, drawn-out course of or barrel our approach by way of it and drive the change to occur, our collective aim must be no matter supplies one of the best human end result to us on the opposite aspect. I strongly consider that automation not solely propels our business ahead but in addition units the stage for a extra worthwhile future.”

And there’ll at all times be a marketplace for small-batch, handmade items. Masters of their craft—cultivators, trimmers, edibles cooks, extractors, and others—can’t compete with giant operations on value or quantity, however craft items discover an enthusiastic reception amongst connoisseurs.

What’s subsequent?

As Root Sciences’ Tillson talked about, know-how turns into extra advanced and developments happen extra rapidly over time, because of the best way every new innovation takes benefit of earlier developments. With AI now aiding on each degree from ideation to execution, research-and-development cycles could attain warp velocity. However that doesn’t imply adoption will preserve tempo.

“It’ll in all probability take one other three to 5 years for us to see some actually superior stuff in automation developments, however there’s a necessity throughout the chain, particularly for the craft guys,” mentioned Bryan Gerber, CEO of pre-rolled cone producer Hara Provide. “They want extremely specialised tools, whereas the Curaleafs of the world are simply on the lookout for extremely environment friendly equipment to allow them to pump out numbers.” Multistate operators, whose enterprise mannequin depends on effectivity throughout the board, usually have the monetary assets to undertake new applied sciences early of their life cycle. Maintaining a tally of the processes and tools they favor can present clues about what applied sciences may have endurance, he added.

As for the classes almost certainly to be impacted by rising automation developments, particularly these incorporating AI, Gerber’s guess is on area of interest merchandise within the shopper items house. “I believe persons are on the lookout for that have and are prepared to pay extra for it,” he mentioned, thereby making innovation within the sector extra possible.

The drinks sector is primed to learn, as nicely, based on Iron Coronary heart Canning Vice President of Gross sales Roger Kissling. Iron Coronary heart operates an automation-heavy cell canning plant that packages drinks on the supply, liberating producers from the expense of working in-house operations. “I consider the beverage class has immense potential in the case of analyzing automated datasets,” he mentioned. “It’s well-positioned to fulfill a specific sort of shopper different merchandise within the business aren’t geared towards. If we are able to use know-how to tailor drinks to be a bit extra ‘practical’—in different phrases, mood-boosting, anxiety-reducing, or stress-relieving—it can open hashish up to a much wider viewers.”

Much more potential awaits within the analysis lab, the place the plant and its compounds nonetheless signify an enormous, unexplored frontier. “Final 12 months on the Emerald Science Convention, I met a bunch that had developed an artificial cannabinoid to quantitatively shrink the dimensions of tumor cells in a rat,” Partansky mentioned. “That was the primary time I’ve seen one thing scientifically examined, and it was completed by trial and error to develop a novel cannabinoid not discovered within the plant. Now, think about utilizing a robotic fleet powered by AI brute-forcing hundreds of experiments a month. Take into consideration how a lot we may change. What would possibly the world seem like after we use the ability of AI to unlock the secrets and techniques of the endocannabinoid system as soon as and for all? It’s a future I’m excited to be part of, and so ought to everybody else within the business.”

A task for augmented actuality?

You’ve used them to immerse your self in video games like Beat Saber and Resident Evil, however may augmented actuality (AR) headsets have a spot within the hashish business? A workforce at Wageningen College & Analysis within the Netherlands, led by robotics and automation researcher Joseph Peller, PhD, is wrapping up 4 years of analysis into how AR is likely to be used to enhance cultivation practices. Their findings point out merchandise like Apple’s new Imaginative and prescient Professional may assist cultivators estimate yield just by scanning the tops of vegetation.

And that’s simply the tip of the proverbial iceberg, based on thought leaders embedded within the business day in and time out.

“Think about this,” mentioned Prodigy’s Beginin. “You can be in California and placed on a pair of glasses that can help you stroll by way of a develop in Massachusetts. You possibly can transfer your palms and watch a robotic contact a plant for you 3,000 miles away. Our director of innovation relies in Alaska. If we are able to [virtually] stand in that freezing-cold lab with the operator and inform them what they’re doing incorrect with out having to go away our properties? That’s phenomenal.”

Vape-Jet’s Hoitt envisions a job for AR paired with robotics, automation, and AI. In his futuristic imaginative and prescient, the mixed applied sciences not solely free their human collaborators from bodily unpleasantries but in addition have company.

“Think about a bot that may undergo your cultivation house and say, ‘Oh, that cola is ideal. I’m selecting it right now.’ It sounds nice, however I don’t consider that’s one of the best software for AR due to its limitations,” he mentioned. “Now, should you mix AR with robotics and automation and use that for crop enter, the concept is likely to be extra helpful. That approach, you’ll have higher imaging sensors, [the grow worker] gained’t get drained, your imaginative and prescient system gained’t get sweaty, and also you gained’t ever end up having to stroll by way of humid environments with a bunch of electronics strapped to your head.”